Tank Explorer

Tanks are designed and manufactured in many different variations for the safe storage of a range of products. We can inspect storage tanks containing high and low flashpoint products such as diesel, kerosene, gasoline, lube oil, glycol, water, naphtha, among others.

Tank floor corrosion. Let our Explorer get to the bottom of it.

Safe, trusted. Entirely Intero.

Our services help you to:

- Extend your license to operate

- Assess tank integrity without going offline

- Facilitate maintenance planning

Our inspections are done according to industry standards, e.g. API-653, EEMUA 159, and use intrinsically safe equipment (UL, ATEX) where required. In addition, our tank inspections are fast and cost-effective and require no downtime or disruption to your business operations.

We provide tank inspections for:

- Petrochemical industries

- Water industries

- Nuclear industries

- Airports

Intero Integrity Services’ storage tank inspections will ensure the safety, reliability and integrity of your storage tank, while providing more efficient operations.

We offer skilled personnel, a global reach and the best available equipment to ensure a high-quality inspection solution you can trust.

Tank Explorer by Intero. The standard for your online tank inspection service.

Over 1000 storage tanks successfully inspected non man entry since 1997.

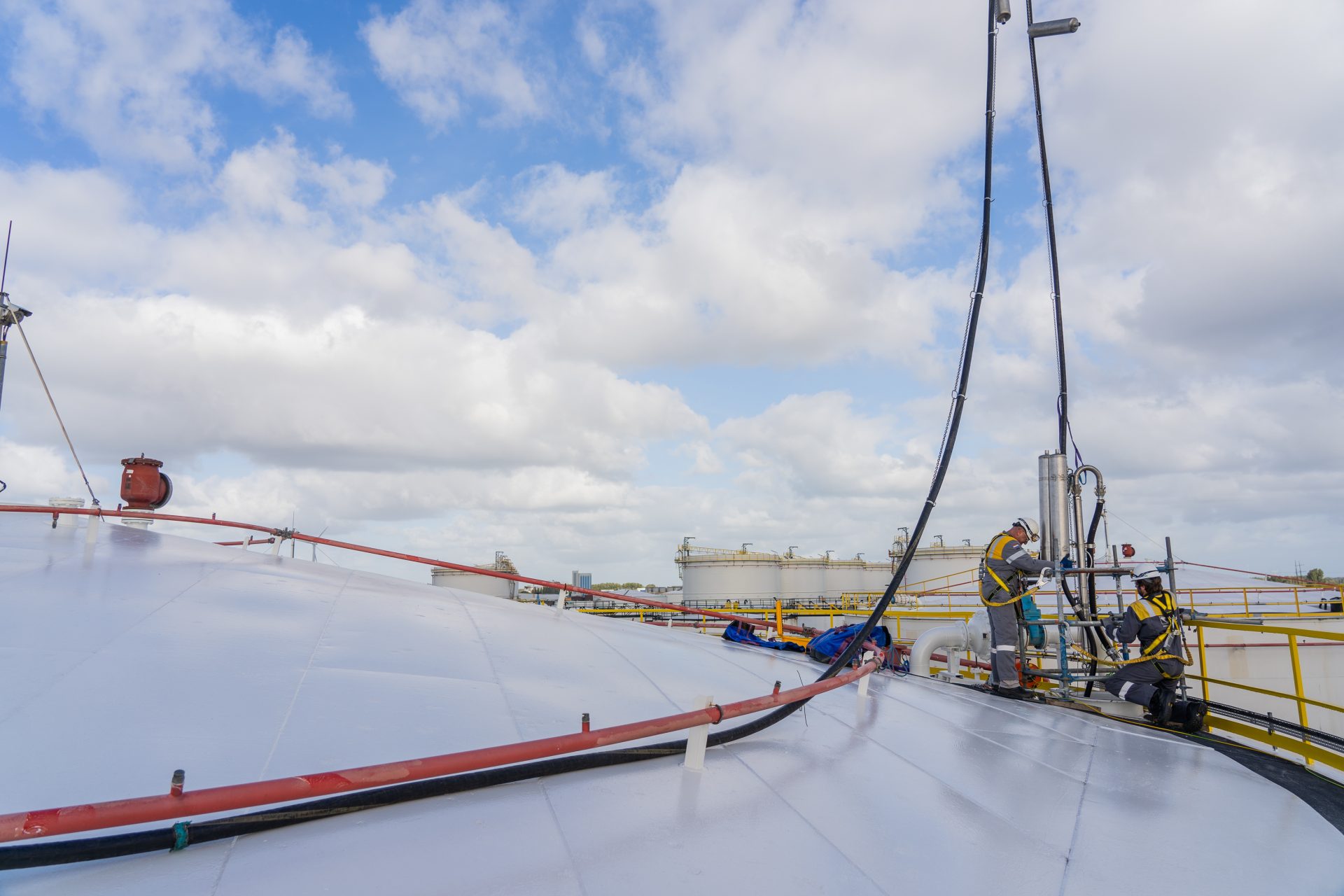

Tank Explorer - in-service robotic bottom inspection

Due to regulatory demand or internal integrity reasons storage tanks have been taken out of service for inspections like tank bottom corrosion assessments and bottom settlement inspections. With Intero's ultrasonic (UT) Explorers this inspection can be performed during operation, it now means there is no longer any need to empty the tank. In this way you can significantly reduce the overall operational cost impact of inspection and downtime, while cleaning costs and product waste are reduced too.

Our robotic Tank Explorer provides inspection according to the API 653 standards and EEMUA 159, or customized to the customers need.

The intrinsically safe tank bottom explorer uses UT sensors to detect any variation in thickness of the bottom plate and can differentiate between product and soil side corrosion. Our sophisticated navigation system and cameras assure that we can cover the full surface of your tank bottom or as required and can give you a view at your tank bottom (product and tank design permitting).

Tank bottom settlement measurements are commonly taken when the tank is out of service and empty. However, the same data set obtained from the robotic online tank floor corrosion inspection can also be used to assess the tank bottom settlement. This will not only provide a more accurate and a realistic settlement assessment with the product in the tank but also provide a full, high resolution settlement display of the tank bottom rather than the spot checks on selected locations using out of service inspection.